1. Ensure the Competence of Installation Personnel

Owners SHALL ensure that installation personnel are professionally competent, professionally qualified and are provided with adequate instructions for carrying out the work.

2. Ensure Proper Commissioning and Handover

Owners SHALL ensure that the test loading, test drive and commissioning inspection have been properly executed and that the handover load has been properly completed. Owners SHALL ensure that components, electrical connections and steel structures of the product have been inspected and certified as defect-free.

3. Documentation

At handover, check with your supplier that you have received all of the documents that you are supposed to have and that they correspond to the product. Owners SHALL ensure that all product documentation is available and is in the agreed language.

4. Ensure Availability of Tools and Equipment

The owner must ensure that tools and equipment are available for installation, in accordance with the sales contract.

Lifting equipment, man lifters and test loads may be required.

Hand lines, securely attached to the building structure, should be used for lifting or lowering materials and tools. Use proper safety equipment to prevent objects from falling when working in high places.

5. Allow Sufficient Time

Owners must ensure that sufficient time has been reserved for installation and testing.

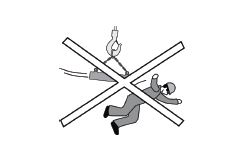

6. Prevent Unauthorized Access to the Site

Owners must prevent unauthorized persons and bystanders from walking on or below the work site.

Ensure that the secured area is spacious enough to prevent injuries which could occur as a result of falling components or tools.

7. Minimize the Risks of Moving Machinery

Make sure that there is no possibility for personnel or body parts to be struck, crushed or compressed by moving machinery.

Owners must secure the area so that installation personnel are not at risk from the movements of machines, automatic doors or adjacent hoists at the installation site.

Ensure that machinery and equipment cannot start accidentally and cannot move during installation and servicing. Maintain sufficient free space in the working area to reduce risks. Moving parts should be properly shielded with guards to prevent entrapment. Safety devices must never be overridden.

Be prepared in case equipment moves in the wrong direction during testing.

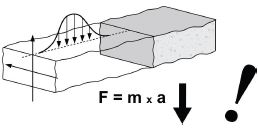

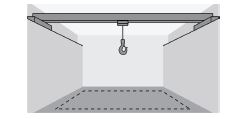

8. Ensure that the Support Structure is Prepared for the Product

Owners must ensure that the support structure which the product is attached to is designed for the load of the product and meets the specific requirements and tolerances.

9. Check that the Power Supply is Compatible

Check that the supply voltage and frequency match the requirements of the product. Check that the installed bus bars are suitable for the product.

10. Safety Devices must be Restored to Operational Status

Ensure that any safety devices which have been bypassed for testing purposes have been restored to full operational status before allowing the product to be used for normal operation.

11. Check the Environmental and Space Requirements

Ensure that the operating environment and space reserved for the product in the operating location is suitable for all functions of the product.

12. Check for Dimensional Conformance

Immediately following installation and prior to commissioning, check that the supplied parts conform to the drawings, instructions, parts lists and structural measurements. Discuss any non-conformance with the supplier immediately.

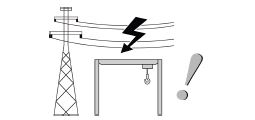

14. Ensure That There are no Hazards from Loose Items.

Check for any electrical hazards in and around the working area and take appropriate steps to minimize them. Only properly trained personnel may perform electrical work on the product and they must use safe methods at all times.

15. Take Precautions if Welding is Done at the Site.

If there is a need for welding to be done at the site: Provide suitable fire extinguishers. Do not allow the product structure or any of the components to be used for grounding. The hook must be isolated to protect it from providing a ground prior to welding. Do not weld on the hook.